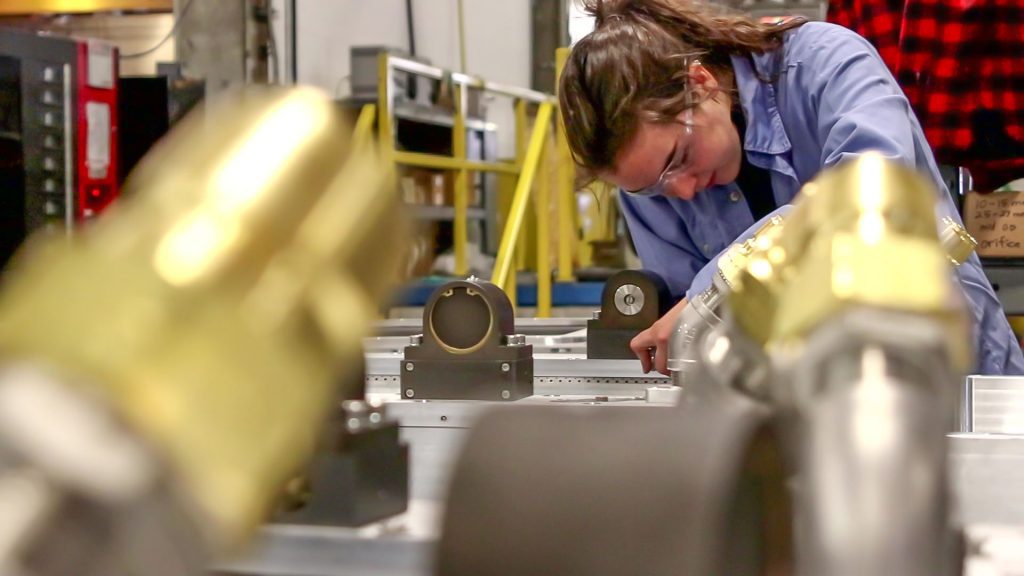

Manufacturing a company that is still thriving and innovating 77 years later is no easy feat. Still, Wagstaff Inc. has managed to do so by investing in their people and new technologies. Leading the manufacturing industry well beyond the Spokane Valley.

Wagstaff made its name by developing the systems and equipment to produce aluminum. More specifically, ingot and billet using direct chill casting methods. Ingot and billet casting are typically not the first things that come to mind when discussing “cutting-edge technology” in an age where computer chips dominate the conversation.

Let’s explain. An ingot is created by melting metal into a liquid form and then pouring it into a large mold to cool and solidify, like melting chocolate and pouring it into a mold to create a chocolate bar once it is cooled. A billet, on the other hand, is metal that is shaped into smaller, more specific pieces of metal. Instead of a Hershey’s bar, it is the Hershey’s Kiss. Throw in Wagstaff’s direct chill casting equipment, and the metal is cooled and created much faster.

Today, Wagstaff has developed the revolutionary APEX™ Rolling Ingot Casting Technology. This automates the molding process, allowing endless molds to be created in minutes while reducing the amount of wasted metal. Wagstaff’s patented, recipe-controlled mold bore adjusts automatically throughout the casing process, which allows it to do some amazing things. For instance, since the APEX machine constantly adjusts during the pouring process, it can create a perfect ingot mold. It is also 25% faster than traditional ingot casting. The APEX casting system can also be changed depending on the desired thicknesses or width in minutes, as opposed to the several weeks it takes for a new mold to be designed and delivered. This revolutionary technology streamlines the manufacturing process to create ingot faster, cheaper, and more energy-efficient since APEX uses less than 10% of the oil required to make standard molds.

“We revolutionized the industry with that new technology,” said Dr. Wade Larson, Chief Human Resources Officer at Wagstaff. But manufacturing a company and culture, now led by the 4th generation of the Wagstaff family, has required its own innovations. “Wagstaff has invested in workforce development from multiple fronts internally,” Larson said. “We are actively developing our own welders and machinists using competency-based learning.”

Larson believes what keeps the company together isn’t meeting quotas but remembering what truly matters. “Our closest customers are 300 miles away. Our local customer is our employees. It’s the employees that make the difference. They’re the ones who matter.” This belief is core to how Bill Wagstaff ran the company, which his daughter and now company President, Barbara Wagstaff Parkes, has continued.

Wagstaff has remained committed to manufacturing in Spokane Valley despite their global reach and rising costs of labor. “It’s expensive to stay in Spokane Valley versus going 15 miles to the east,” Larson said. “Lots of companies do that, but we have never once thought about doing it because we love Spokane Valley. We love the community and this manufacturing environment that we have here.”

Wagstaff has played a pivotal role in advocating for workforce development and implementing programs aimed at introducing high school students to careers in the trades industry. They have supported the creation of several academies and workforce events in recent years. Larson expressed his appreciation for other local businesses’ support whenever he reached out.

“Wagstaff supported the concept that I had to start the Production and Manufacturing Institute. So I reached out to other businesses in our sector to see if they wanted to be involved, and the outpouring of support was inspiring,” Larson said. “The Institute is privately funded because these companies want to build the future here in Spokane Valley. That’s something special, that’s why Wagstaff is here, and that’s why we’re going to continue to be here.”