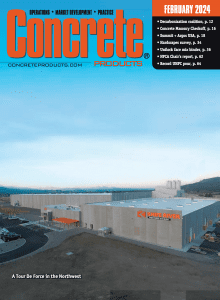

Building Stronger Futures: Knife River’s Cutting-Edge New Precast Plant

The Inland Northwest’s construction landscape is changing with the recent opening of Knife River’s state-of-the-art precast concrete facility. At 45 acres and an imposing 185,000 square feet, the new plant in Newman Lake replaces the company’s 65-year-old Spokane operation with a high-tech, sustainable facility poised to transform the regional industry.

With its new plant, Knife River has raised the bar for innovation and sustainability in precast manufacturing. The company is driving advancements that improve productivity, quality, safety and environmental performance, while bringing precast construction indoors to accelerate schedules and reduce weather-related delays.

The fully enclosed plant has ample room for growth as the need for prefabricated solution demands continue to rise. It can produce up to 10,000 square feet of panels, 1,800 square feet of hollow core slab and both standard and long-span girders daily. This enables Knife River to supply critical projects across the Northwest.

A pair of 250-foot casting beds, outfitted with overhead cranes, accommodate girders that are up to 300,000 pounds and 12-plus feet tall. The robust foundations ensure quick changeovers between products like slabs, girders and bulb tees. Knife River designed the beds’ capacity to handle long bridge spans in collaboration with states’ departments of transportation.

At the core is a high-volume concrete batch plant utilizing dual mixers and an upgraded electric delivery system. Concrete travels rapidly from mixing to casting via automated rail-mounted buckets. This reduces waste, boosts quality control and improves safety by limiting exposure.

Sustainability is integral to the plant’s design and operations. Features like electric cranes, closed-loop concrete curing, solar readiness and on-site aggregate harvesting dramatically cut environmental impacts. The plant is targeting the first-ever Concrete Sustainability Council (CSC) certification for a North American precast facility. The CSC system typically applies to all products manufactured and supplied by the plant.

The plant also reflects Knife River’s focus on its workforce and community. More indoor production and automation promote safety, while open office spaces foster collaboration. According to Knife River Regional Manager Blake Johnson, “We’re taking what had been done in the field and doing it better in a controlled manufacturing site. There’s no rain or sleet and we’re reducing volatility and enhancing quality.” The company draws on its 100-plus years of experience while embracing the future.

Long History, Bright Future

Knife River’s roots in the Northwest run deep, beginning with Central Pre-Mix Concrete founded locally in 1959. When Oldcastle Infrastructure acquired Central Pre-Mix in 1987, it became the region’s primary precast producer.

MDU Resources Group purchased Oldcastle’s Northwest assets in early 2020, integrating them into its Knife River subsidiary. This joined Knife River’s 60-year-old Oregon precast operations with Central Pre-Mix’s 60 years of experience in Spokane.

According to Johnson, “We’re building on decades of work by the Murphy family and Central Pre-Mix team who did a fantastic job building the infrastructure that allowed us to grow.” The company honors this legacy while modernizing operations.

The acquisition included Central Pre-Mix’s longtime Spokane Valley plant. This outdoor facility off Carnahan Road served as Knife River’s manufacturing hub while the new Newman Lake plant was under construction.

Now Knife River’s most advanced plant, the Newman Lake facility sets a new bar for productivity, quality and working conditions. It also provides the capacity to pursue major projects as infrastructure needs grow.

Serving Customers, Community

The Knife River stamp can be found on many of Spokane’s most recognizable buildings, including a pair of Walt Worthy projects – the Davenport Tower, the first hotel that exclusively utilized precast construction, and the Davenport Grand which optimized the design process from the Tower, resulting in faster construction.

Rock Pointe, Riverview Corporate Center, the Amazon Distribution Center on the West Plains and One Spokane Stadium all benefited from collaboration with Knife River while over 1,000 pieces of precast structure for the seating, stairs and passageways at Climate Pledge Arena in Seattle were manufactured by Knife River and shipped from Spokane.

Baker Construction & Development, Inc. worked with Knife River on the Tesla Sales and Service Facility in Liberty Lake,

“They did a great job helping us with the accelerated timelines and unique material shortage struggles we were facing post-Covid,” said Brooke Baker-Spink, chief development officer with Baker. “We are looking forward to partnering with them more in the future.”

The Max J. Kuney Company is one local contractor that is enthusiastic about the new Knife River site and the level of efficiency it is expected to deliver.

“Having a top-notch precast company in Spokane has been a great benefit to many projects,” said President Max Kuney Jr. “We are looking forward to the added capacity their new, state-of-the-art facility will bring and look forward to working with them for many years to come.”

Knife River also gives back to the community. The organization is a significant contributor to the Bite2Go program through Second Harvest and partners with schools to educate students about manufacturing and careers in trades.

The new plant created over 80 full-time local jobs, with plans to expand to 150 workers. Providing family-wage jobs and benefits is central to Knife River’s mission, with values that embrace people, quality, safety and the environment.

Setting New Standards

The Knife River brand goes back to 1917 when the company was founded near the Knife River in North Dakota. There are now over 6,000 employees that call Knife River home, working in 14 states across the Western U.S. On June 1, 2023, Knife River completed its spinoff from MDU Resources group and became an independent, public company trading on the New York Stock Exchange.

Overall, Knife River’s new facility reflects a builder ready for the future yet staying true to its foundations. It sets a standard for how manufacturers can evolve while honoring team members and supporting communities. This enduring mission ensures Knife River will continue shaping the Northwest construction landscape for decades to come.

Interested in learning more about Knife River?

Click the button below to read their feature in

Concrete Products Magazine.